As new material handling technologies enter the market, conveyors remain a critical part of every automation system. Material handling is a field involving the transport, storage, and control of products through the processes of manufacturing, distribution, consumption and disposal of related materials. The industry focuses on methods, mechanical equipment, systems and related controls used to achieve necessary functions. The use of conveyors is the backbone of material handling. Conveyors are a piece of machinery that moves material from one place to another and they come in different types such as vertical reciprocating conveyors, food grade conveyors, stainless steel conveyors, and accumulation conveyors.

Conveyors are useful when applications call for the transportation of heavy or bulky material or products with a variety of shapes and sizes. Choosing the correct conveyor depends on the type of product handling needed. The product dimension, weight, throughput, and variability are considered. Understanding the surrounding environment and power requirements is also important.

Conveyors are useful when applications call for the transportation of heavy or bulky material or products with a variety of shapes and sizes. Choosing the correct conveyor depends on the type of product handling needed. The product dimension, weight, throughput, and variability are considered. Understanding the surrounding environment and power requirements is also important.

The following conveyor types are available from Thomas Conveyor & Equipment. Our sales engineers will help determine which conveyor type suits your application.

Gravity Conveyor: Gravity, non-powered conveyor is typically used in truck off loading, package sorting and assembly areas. Being the cheapest form of conveyor, gravity conveyor is lacking in product control.

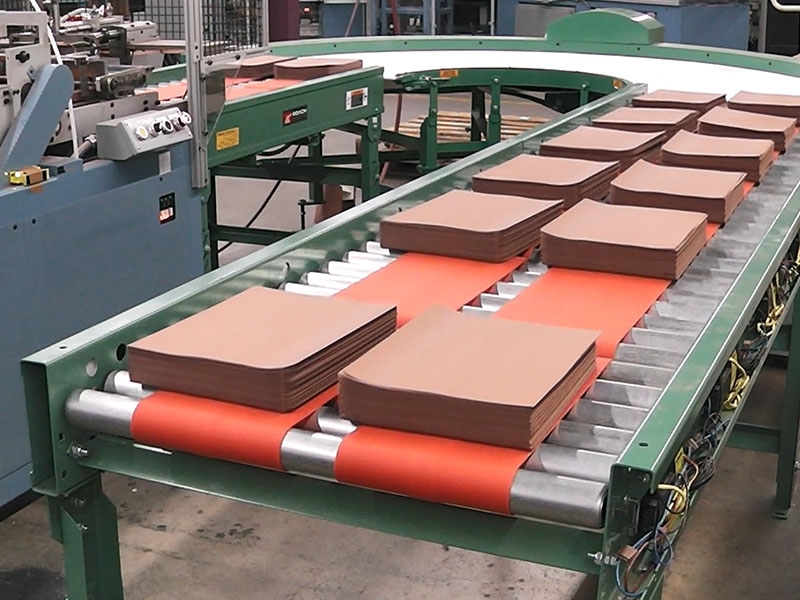

Belt Conveyor: Belt Conveyor is used in package handling, raw material handling, and small parts transportation. Belt conveyors can be used for elevation changes in incline or decline applications.

Live Roller Conveyor: This powered roller conveyor is typically used in general transport when product accumulation is not required. Live roller conveyor is used in package handling application and is ideal for light to medium product loads.

Live Roller Conveyor: This powered roller conveyor is typically used in general transport when product accumulation is not required. Live roller conveyor is used in package handling application and is ideal for light to medium product loads.

Minimum Pressure Conveyor: Being a powered roller conveyor allows the minimum pressure conveyor short sections of accumulation, general transport of product, and is ideal for medium to light loads, such as package handling.

Zero Pressure Conveyor: This powered roller conveyor is commonly found in distribution centers where there is a wide variety of product width and weight. Buffering of products prior to sortation, and packaging in shipping areas are common applications. Zero pressure conveyors are ideal for picking areas and palletizing areas, and the conveyor is used in high throughput systems.

Drag Chain Conveyor: This pallet conveyor is typically used for handling extremely heavy loads, special pallet configurations and extremely low to high temperature areas.

Roller Conveyor: Roller pallet conveyor is used for handling extremely heavy loads and is ideal for accumulation zones in pack out areas.

Overhead Conveyor: Typically used in paint and finishing lines, trash removal, food packing, and assembly lines, the overhead conveyor is reliable and requires little maintenance.

Table Top Chain Conveyor: Table Top Chain is used in labeling, wash-down, package handling and filling as well as accumulation applications.

Magnetic Slide Conveyor: Magnetic slide conveyor is used in metal stamping, small parts transportation and chip removal applications.

No matter what type of automation system you install, there will more than likely be a conveyor to support your efforts. Let Thomas Conveyor help you select the correct conveyor type for your application. Our systems integrators will ensure your entire manufacturing or distribution facility runs at its peak performance level!