-

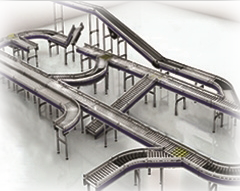

Conveyor Equipment

- Belt Conveyors >

- Powered Roller Conveyors >

- Gravity Roller Conveyors

- Conveyor Accessories >

- Stainless Steel and Food Grade Conveyor Systems >

- Extendable / Accordion Conveyors

- Vertical Conveyors

- Bulk Handling Conveyors

- Transfer and Merge Conveyors

- Overhead Conveyor and Monorail Conveyor Systems

- Custom Equipment

- Sortation Systems

- Ergonomic Equipment

- Mezzanines & Lifts

-

Packaging & Warehouse

- Pallet Flow Racking and Case Flow Racking Systems

- Gorbel Cranes and Monorails

- Guard Rail and Collision Awareness

- Safety Fencing & Machine Guards

- Palletizers

- Case Former / Case Erector

- Case Sealers >

- Conveyor Guarding

- Metal Detection Equipment

- Automatic Strappers

- Pallet Stackers / Pallet Dispensers

- Stretch Wrapping Equipment

- Modular Office

- Robotic Handling

- Industries Served

- Products And Equipment

- About Us

Lead Your Industry with System Solutions

Thomas Conveyor & Equipment Co. specializes in crafting state-of-the-art solutions across various industries. Step into a world where efficiency reigns supreme, featuring a comprehensive array of products tailored to your unique needs. Whether you're seeking the versatility of bulk handling conveyors, the simplicity of gravity roller conveyors, or the reliability of belt conveyors, our offerings are meticulously designed to transform your operations.

Ready to take the next step? Our application engineers are here to guide you. Reach out today by calling (844) 220-0086 or filling out the form on our contact page. Your path to streamlined efficiency starts now.

Lead Your Industry with Conveyor System Solutions

Discover a partnership dedicated to reshaping industries – Thomas Conveyor & Equipment Co. Our purpose goes beyond products; it's about igniting solutions that redefine sectors. Acknowledging the distinct challenges each industry faces, we've curated a suite of transformative conveyor system solutions. From the entry of raw materials to the exit of finished products, our technologies weave an intricate tapestry of efficiency, precision, and success.

Your industry's challenges define it, and our solutions redefine them. Step into a realm of unparalleled efficiency and innovation. Ready to begin? Connect with our application engineers now. Call us at (844) 220-0086 or fill out the form on our contact page to embark on the journey of transforming your operations.