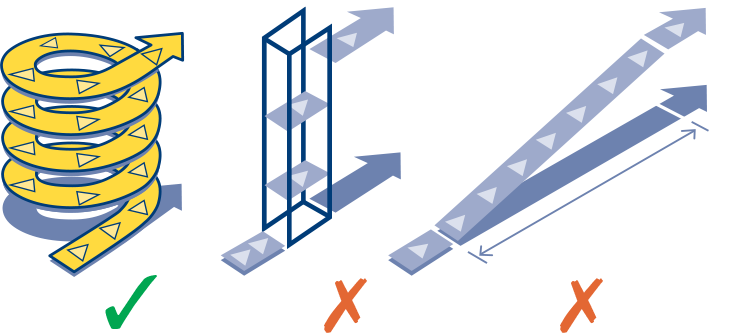

The SpiralVeyor SV Series Vertical Conveyor utilizes a lateral roller system patented by AmbaFlex™ which eliminates controls and sensors. Its continual motion provides a superior advantage for unstable products and high production speeds.

The SpiralVeyor SV is a great choice for transporting totes, crates, containers, cartons, trays, bags and packaged bottles.

Features:

- Only one drive is needed

- Continuous elevator

- Space-saving vertical configuration

- High throughput

- Patented roller design

- Multiple belt options available, including with or without high friction

- Belt maintenance can be done without using tools

- Transports heavy items even if not positioned centrally on the belt

- Elevation up or down (or reversible)

- CE certified and 100% intrinsic safety

Operating Conditions:

- Dry

- Wipe down

- Wash down (economic)

- Wash down (total)

Specifications:

- Belt width: 300-600 mm | 12-24"

- Belt length: up to 200 ft

- Multi-belt Functionality: 1-3 parallel belts

- Load: up to 50 kg/m | 34 lb/ft per belt

- Speed: up to 60 m/min | 200 fpm

- Elevation: Standard 50 ft, but custom elevations can be configured

- Mild steel, coated/ high corrosion resistant/100% stainless steel wash down

Belt Width Recommendations:

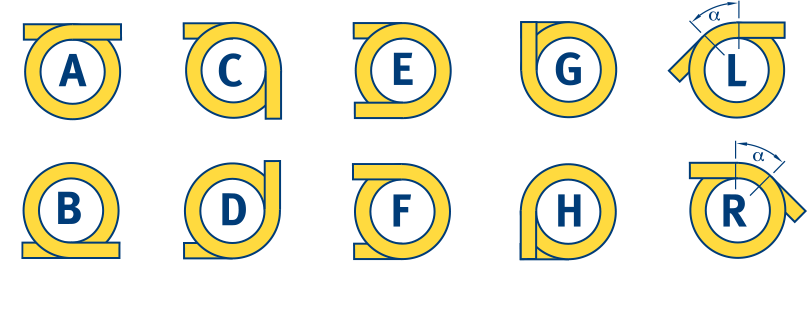

- For narrow belt width, we recommend the SpiralVeyor™ SVs-series

- For wider belt configurations, we recommend the SpiralVeyor™ SVe-series

- For double or triple parallel product flows, we recommend the SpiralVeyor™ X-configuration series

- For smaller belt width or mass flow applications, we recommend the SpiralVeyor™ SVm-series.

Applications

For more information on the SpiralVeyor SV vertical conveyor please contact a Thomas Conveyor & Equipment Automation Engineer at 844 220 0086 or click on the Contact Us button above.