-

Conveyor Equipment

- Belt Conveyors >

- Powered Roller Conveyors >

- Gravity Roller Conveyors

- Conveyor Accessories >

- Stainless Steel and Food Grade Conveyor Systems >

- Extendable / Accordion Conveyors

- Vertical Conveyors

- Bulk Handling Conveyors

- Transfer and Merge Conveyors

- Overhead Conveyor and Monorail Conveyor Systems

- Custom Equipment

- Sortation Systems

- Ergonomic Equipment

- Mezzanines & Lifts

-

Packaging & Warehouse

- Pallet Flow Racking and Case Flow Racking Systems

- Gorbel Cranes and Monorails

- Guard Rail and Collision Awareness

- Safety Fencing & Machine Guards

- Palletizers

- Case Former / Case Erector

- Case Sealers >

- Conveyor Guarding

- Metal Detection Equipment

- Automatic Strappers

- Pallet Stackers / Pallet Dispensers

- Stretch Wrapping Equipment

- Modular Office

- Robotic Handling

- Industries Served

- About Us

Conveyor Accessories

Conveyor Parts & Accessories: stops, guard-rail, brakes, roller sleeves and additional accessories. Conveyor Accessories are components required to enhance a conveyor application or add to existing conveyors to improve performance and safety.

Gravity Roller Butt Spurs - Galvanized Steel

Galvanized Steel Gravity Roller Butt Spurs are used to divert off or merge on main trunk line conveyors at various angles. They are often used when several lines transfer onto a main conveyor line from work stations or similar applications.

Gravity Roller Butt Spurs - Steel

Steel Gravity Roller Butt Spurs are used to divert off, or merge on, main trunk line conveyors at various angles. They are often used when several lines transfer onto a main conveyor line, from work stations or similar applications.

Medium Duty Manual Roller and Blade Stops (for Gravity Conveyors)

Medium Duty Manual Roller and Blade Stops are used when automatic line control is required on conveyors lines, such as accumulation, indexing, inspection stations, etc. These particular stops are often used on variable pressure accumulators and live roller conveyors.

Medium Duty Pneumatic Roller and Blade Stop (for Gravity Conveyors)

Pneumatic Roller and Blade Stops are designed to stop or reroute your conveying equipment’s path and are used to improve usability and customize your conveying setup.

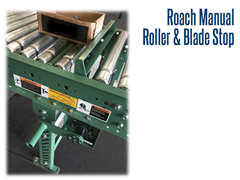

Manual Roller and Blade Stop

Manual Roller and Blade Stops are used where manual line control is required such as assembly work stations & shipping areas. They are often used with power and gravity conveyors.

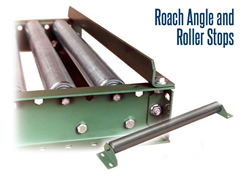

Angle & Roller Product Stop

Angle & Roller Product Stops are designed to stop or reroute your conveying equipment’s path and are used to improve usability and customize your conveying setup. Both Angle & Roller Stops serve as an economical means to stop goods at a given fixed point.

Butt End Product Stops

Conveyor Product Stops are designed to stop or reroute your conveying equipment’s path and are used to improve usability and customize your conveying setup. Stops are often used in conjunction with conveyor components, such as transfers and pushers, to align products or coordinate processes.

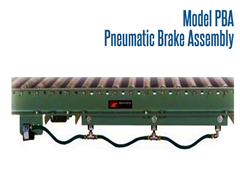

Pneumatic Brake Assembly, Model PBA

A pneumatic brake can be used in a wide variety of applications. Work in process, product accumulation, and product indexing can all be pre-formed with a brake or a series of brakes in tandem.

Traffic Cop

Traffic Cops efficiently control smooth product flow from one conveyor onto another. It allows products from one line of traffic to flow freely without interference from another intersecting line of traffic.

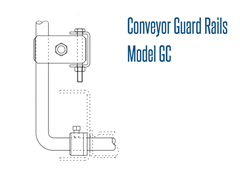

Guard Rails

Guard Rails keep product from straying over the edge of conveyor runs and come in a variety of styles to accommodate varying needs.

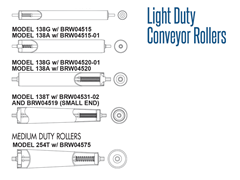

Conveyor Rollers

Conveyor Rollers allow a gravity conveyor to move the load without utilizing motor power sources, usually down an incline or through a person pushing the load along a flat conveyor.

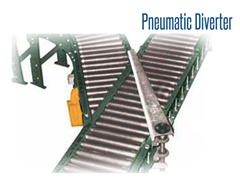

Roach Pneumatic Diverters

Roach Pneumatic Diverters are used to divide the flow of product or cartons into a predetermined lane or flow. They merge multiple conveyor lanes to a single lane for labeling, weighing, or other operation.

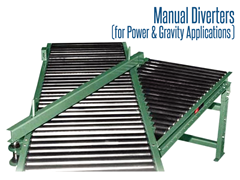

Roach Manual Diverters for Power and Gravity Applications

Manual diverters are used to divert packages off of a main conveying line onto other conveyors. The diverter can be used on powered or gravity conveyors. Diverters feature fixed or power face deflectors to help product along the merge belt.

Roach Screw Type Auxiliary Take-Up (for Live Rollers)

Screw Type Auxiliary Take Ups (for Live Rollers) are the most commonly used manual take up. With a screw take up system, the take up pulley rotates in two bearing blocks which may slide on stationery guide ways with the help of two screws. The tension is created by the two screws which are tightened and periodically adjusted with a spanner.

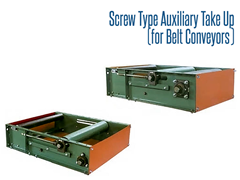

Roach Screw Type Auxiliary Type Take-Up (For Belt Conveyors)

The Roach Auxiliary Type Take-Up (For Belt Rollers) is the most commonly used manual take up. Take ups ensure adequate tension on the conveyor belt.

Nose-Over Brackets

Nose-Over Brackets are used to smoothly bridge the transition of inclined or decline bed section to a horizontal bed section. These brackets may be attached to slider bed or roller bed belt conveyors.

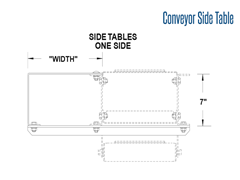

Side Tables

Side Tables can add additional space to aid workers in assembly operations. A side table can be mounted on roller bed, slider bed and boxed slider bed belt conveyors. Side tables provide safety for production workers as well as additional space for assembly.

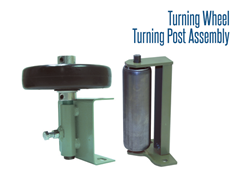

Turning Wheel/Turning Post Assembly

Turning Wheel and Turning Post Assemblies are commonly used in applications with converging or diverging spurs. They are ideally used where numerous lines must transfer onto a main conveyor line from work stations or other similar operations.

Motor Drive Assembly

A Roach Motor Drive Assembly is a complete 1/3 horsepower drive featuring Baldor motor and Boston reducer including motor, reducer, reducer mounting plate (“motor base”), no. 50 roller drive chain, chain guard with cover and two drive sprockets.

Conveyor Guard™ Conveyor Guarding

Conveyor Side Rail Guards, End Cap Product Stops, Corner Guards and Leg Guards ensure full protection for personnel working near conveyor lines.

Replacement Conveyor Belting

Conveyor belting is the carrying medium of a belt conveyor system. When ordering belting, please specify which conveyor system you are currently using to obtain the best replacement belting.

Roach Custom Designed Electrical Systems/Component Controls

By implementing custom control systems, your conveyors and controls are able to be modified to provide a full turnkey system that is tailor-made to your specific needs.