-

Conveyor Equipment

- Belt Conveyors >

- Powered Roller Conveyors >

- Gravity Roller Conveyors

- Conveyor Accessories >

- Stainless Steel and Food Grade Conveyor Systems >

- Extendable / Accordion Conveyors

- Vertical Conveyors

- Bulk Handling Conveyors

- Transfer and Merge Conveyors

- Overhead Conveyor and Monorail Conveyor Systems

- Custom Equipment

- Sortation Systems

- Ergonomic Equipment

- Mezzanines & Lifts

-

Packaging & Warehouse

- Pallet Flow Racking and Case Flow Racking Systems

- Gorbel Cranes and Monorails

- Guard Rail and Collision Awareness

- Safety Fencing & Machine Guards

- Palletizers

- Case Former / Case Erector

- Case Sealers >

- Conveyor Guarding

- Metal Detection Equipment

- Automatic Strappers

- Pallet Stackers / Pallet Dispensers

- Stretch Wrapping Equipment

- Modular Office

- Robotic Handling

- Industries Served

- About Us

Plastic Belt Conveyors

Plastic Belt Conveyors are designed for transporting products that require a solid surface.

Plastic Belt Conveyors are just one type of belt conveyors available through Thomas Conveyor & Equipment. Speak to one of our Automation Engineers to get started designing your belt conveyor today!

Series 900, Flat Friction Top Plastic Belt Conveyor, Roach Model 700PB

The Model 700PB, Series 900 Flat Friction Top, Plastic Conveyor is ideal for transport in applications such as packing, testing, inspecting and assembly lines. The design of the friction belt allows cases and boxes to remain firmly gripped to the belt even when conveying at an incline or decline. The belt is able to run smoothly and remain flat throughout the entire operations process.

Heavy Duty Plastic Belt Conveyor, Roach Model HD1200PB

The Model 1200PB, Series 1200 Heavy Duty Plastic Belt Conveyor is a dynamic plastic belt conveyor that offers versatility for extra heavy loads that other conveyors cannot move. It utilizes flat top belting and is quintessential for heavy unit loads and pallet handling. Belt tracking problems are reduced and eliminated.

Heavy Duty Plastic Belt Conveyor, Roach Model HD400PB Series 400

Model HD400PB is a Series 400 Heavy Duty Plastic Belt Conveyor. The series 400 flat top belting is utilized to handle heavy unit loads. The unit is designed to handle footed pallets, raw material rolls, drums, slip sheets, unitized loads, as well as large containers filled with heavy liquids all items that normally can’t be conveyed on roller conveyors.

Series 400, Inline Roller Top Plastic Belt Conveyor, Roach Model 700RT

The Model 700RT, Series 400 Inline Roller Top, Plastic Belt Conveyor was designed to be used in applications that require transportation or temporary accumulation. Roller top conveyors are great for handling containers or crates that have a smooth bottom no matter the material.

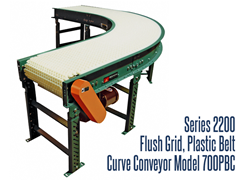

Roach Model 700PBC Flush Grid Plastic Belt Curve Conveyor

The 700PBC is a Series 2200 flush grid, plastic curve belt conveyor which can be used in various line assembly processes such as packing and testing. It is available in 30°, 45°, 60° or 90° curves. S curve formations are also available. Flush grid belts are lighter than flat top belts so they are ideal for longer, wider conveyor runs.

Series 900 Flat Top Plastic Belt Parts Conveyor with Flights, Roach Model PPF

The Model PPF is designed to convey small parts with 2" high standard streamline flights. It offers optional 1" and 4" flight heights and overlapping sideguards. It requires little maintenance, it is easy to clean and can be aligned to bend horizontally or vertically. Due to its low-maintenance design, this conveyor is extremely cost-effective.

Series 900, Flat Friction Top Plastic Belt Conveyor, Roach Model 700FFT

The Model 700FFT, similar to the Roach Model 700PB, is a Series 900 Flat Friction Top, Inclined Plastic Conveyor. It is able to handle heavy boxes and caseloads. The 700FFT is the best option for floor-to-floor inclined or declined carton handling and conveyances. This conveyor is highly adaptable and is also very cost effective.

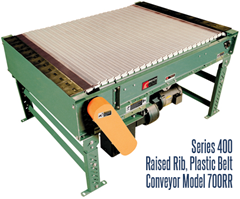

Series 400, Raised Rib Plastic Belt Conveyor, Roach Model 700RR

The Model 700RR is a Series 400, raised rib, plastic belt conveyor great for transporting and transferring cans, bottles, or other small items that are hard to convey. These materials are typically hard to transfer because of stability issues but the raised ribs on the belt act as a buffer and assist in stabilizing products.

Series 400, Transverse Roller Top Plastic Belt Conveyor, Roach Model 700TRT

The Model 700TRT is ideal for applications requiring 90° product transfer on or off, product centering or carton rotation (box turner). Products can be diverted from or merged onto a conveyor with standard transverse mounted rollers in the belt. Belt tracking problems are eliminated with Model 700TRT.

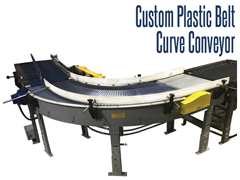

Custom Plastic Belt Curve Conveyor

Custom belt curves are purposed for accommodating tight curves and allowing maximum efficiency in the manufacturing, food processing, distribution and packaging industries.

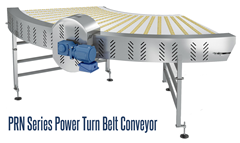

PRN Series Power Turn Belt Curve Conveyor, MCE

The PRN Series Line of Power Turn Conveyors are ideal for the transfer of smaller, fragile objects moving items smoothly and evenly.