-

Conveyor Equipment

- Belt Conveyors >

- Powered Roller Conveyors >

- Gravity Roller Conveyors

- Conveyor Accessories >

- Stainless Steel and Food Grade Conveyor Systems >

- Extendable / Accordion Conveyors

- Vertical Conveyors

- Bulk Handling Conveyors

- Transfer and Merge Conveyors

- Overhead Conveyor and Monorail Conveyor Systems

- Custom Equipment

- Sortation Systems

- Ergonomic Equipment

- Mezzanines & Lifts

-

Packaging & Warehouse

- Pallet Flow Racking and Case Flow Racking Systems

- Gorbel Cranes and Monorails

- Guard Rail and Collision Awareness

- Safety Fencing & Machine Guards

- Palletizers

- Case Former / Case Erector

- Case Sealers >

- Conveyor Guarding

- Metal Detection Equipment

- Automatic Strappers

- Pallet Stackers / Pallet Dispensers

- Stretch Wrapping Equipment

- Modular Office

- Robotic Handling

- Industries Served

- About Us

Accumulation Conveyors

When designing a conveyor system for your business, there will no doubt come a time when you decide you’ll need some sort of accumulation functionality. Thomas Conveyor & Equipment company is here to help! An accumulation conveyor can be used in a conveyor system prior to sortation, when merging product together, or at the end of the line where an operator will unload.

What sets an accumulation conveyor apart from other powered conveyors?

They assist in the control of the rate of flow of products through a production process. Rather than a continuous flow of products like other powered roller conveyors, the accumulation conveyor starts and stops the movement of loads automatically, allowing for storage and metering or batch advancing of loads. This is often achieved using accumulation zones, sensors, air valves and brakes. The conveyor’s powered roller uses motorized rollers to drive the conveyors eliminating the need for drive belts, chains or line shafts.

There are a variety of designs and customizations to consider when designing your accumulation conveyor, including the amount of pressure (zero to variable pressure), and the size and weight of the materials being conveyed (light, medium, or heavy-duty). No matter your needs, Thomas Conveyor can work with you to design a system specific to your industry. Call us today to speak with an application engineer and view all of our accumulation conveyors below.

Light Duty Variable Pressure Live Roller Accumulator Conveyor, Roach Model 138VP

Light Duty Variable Pressure Live Roller Accumulation Conveyor which can transport up to 100 lbs. per foot with a 2-1/2% minimum backpressure. One of the simplest methods for accumulating cartons, boxes, etc., its basic design eliminates complicated adjustments found in other conveyor systems.

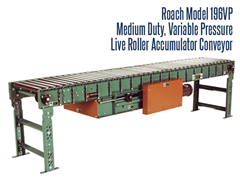

Medium Duty Variable Pressure Live Roller Accumulator Conveyor, Roach Model 196VP

Roach Model 196VP variable pressure accumulator conveys medium weight goods safely and with minimum backpressure. In a distribution or manufacturing operation, accumulation conveyors are commonly used to transport and accumulate cartons or unit loads so that they are efficiently queued up and fed into sorting, wrapping, palletizing, strapping or other processes.

Medium Duty Zero Pressure Live Roller Accumulator, Roach Model SZ196ZPA Smart Zone™

The Roach SZ196ZPA Smart Zone™ safely accumulates packages with zero back pressure utilizing zone singulation operation. Zero pressure conveyors will use a type of sensor to segregate the conveyor into various sized zones that will accumulate your product.

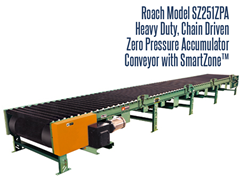

Heavy Duty Zero Pressure Accumulator, Roach Model SZ251ZPA Smart Zone™

A Roach SZ251ZPA Smart Zone™ is a heavy duty zero pressure accumulator, designed to accumulate heavy products, containers, and pallets in 5’ zones. The Roach Conveyor design incorporates photoelectric sensors, instead of sensor rollers, eliminating many common problems associated with conveying wooden pallets.

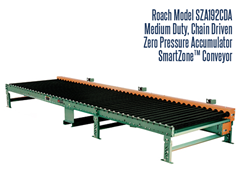

Medium Duty Chain Driven Zero Pressure Accumulator, Roach Model SZA192CDA Smart Zone™

Model SZA192CDA are designed to safely bring together medium duty loads in 5' zones. The Smart Zone™ incorporates photoelectric sensors, instead of sensor rollers, to detect product loads, which eliminates many problems associated with sensor rollers. Products do not touch during accumulation and are singulated individually off of the conveyor.

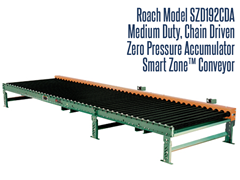

Medium Duty Chain Driven Zero Pressure Accumulator, Roach Model SZD192CDA Smart Zone™

Roach's Medium Duty Chain Driven Zero Pressure Accumulator Conveyors are designed to safely bring together medium duty loads in 5' zones. The Model SZD192CDA Smart Zone™ incorporates photoelectric sensors, instead of sensor rollers, to detect product loads which eliminate many problems associated with sensor rollers.

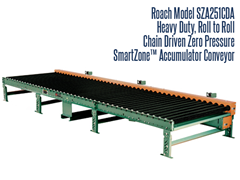

Heavy Duty Chain Driven Zero Pressure Accumulator, Roach Model SZA251CDA Smart Zone™

SZA251CDA Smart Zone™ is a heavy duty roll-to-roll chain-driven zero pressure accumulator, designed to safely accumulate heavy products such as castings, drums, containers and heavy pallet loads in 5’ zones.

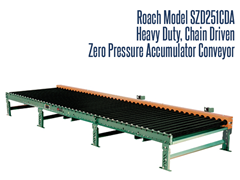

Heavy Duty Chain Driven Zero Pressure Accumulator, Roach Model SZD251CDA Smart Zone™

The Model SZD251CDA SMART ZONE™ is a heavy duty roll-to-roll chain-driven zero pressure accumulator, designed to safely accumulate heavy products in 5’ zones.

Medium Duty Line Shaft Driven Zero Pressure Accumulator, Roach Model SZ796LSZ Smart Zone™

The Model SZ796LSZ Smart Zone™ is a horizontal line shaft driven conveyor, designed for zero pressure accumulation of product. It features SmartZone photo eye technology. Model SZ796LSZ quietly accumulates a wide variety of product sizes and features no minimum weight limitations.

Line Shaft Driven Zero Pressure Accumulator, Roach Model 796LSZ with Sensor Rollers

The Model 796LSZ Smart Zone™ is a horizontal line shaft driven conveyor, designed for zero pressure accumulation of product. It quietly accumulates a wide variety of product sizes and features no minimum weight limitations. Each zone features positive braking of each roller in the zone during accumulation. Product may be released in singulation or slug fashion.

Poly-V Photo Eye Controlled Powered Roller Accumulator Conveyor, Roach Model 796 PRA

The Model 796PRA is a photo eye controlled powered roller zero pressure accumulator. The motorized rollers eliminate drive belts, chains or line shafts. Designed for light to medium duty applications, it can handle up to 15 lbs per roller or 70 lbs per zone.

Poly-V Photo Eye Controlled Powered Roller Accumulator Curve, Roach Model 796 PRAC

The model 796PRAC assists in the control of the rate of flow of products through a production process. Rather than a continuous flow of products like other powered roller conveyors, the accumulation conveyor starts and stops the movement of loads automatically, allowing for storage and metering or batch advancing of loads. This is often achieved using accumulation zones, sensors, air valves, and brakes.