-

Conveyor Equipment

- Belt Conveyors >

- Powered Roller Conveyors >

- Gravity Roller Conveyors

- Conveyor Accessories >

- Stainless Steel and Food Grade Conveyor Systems >

- Extendable / Accordion Conveyors

- Vertical Conveyors

- Bulk Handling Conveyors

- Transfer and Merge Conveyors

- Overhead Conveyor and Monorail Conveyor Systems

- Custom Equipment

- Sortation Systems

- Ergonomic Equipment

- Mezzanines & Lifts

-

Packaging & Warehouse

- Pallet Flow Racking and Case Flow Racking Systems

- Gorbel Cranes and Monorails

- Guard Rail and Collision Awareness

- Safety Fencing & Machine Guards

- Palletizers

- Case Former / Case Erector

- Case Sealers >

- Conveyor Guarding

- Metal Detection Equipment

- Automatic Strappers

- Pallet Stackers / Pallet Dispensers

- Stretch Wrapping Equipment

- Modular Office

- Robotic Handling

- Industries Served

- About Us

Mezzanine Gates & Railings

Thomas Conveyor provides OSHA compliant fall protection for mezzanines, work platforms and safety platforms. We have a wide variety of mezzanine railings, safety gates, access gates, pallet gates and sliding gates for your mezzanine or work platform.

Stairways should be protected with safety rails and safety gates. Mezzanine access points should have guard rails, ladder safe zones and protected loading areas. Thomas Conveyor & Equipment offers a variety of solutions for elevated loading access points in controlled areas and warehouse worker safety, including modular safety rail systems, gates and one way flow solutions to allow products to pass through an area without leaving an access point open.

Modular Mezzanine Railing Systems

Modular railing systems are designed to clearly define pedestrian walkways, loading docks, production areas, and assembly lines. They increase the safety and operational efficiency of a mezzanine system while conforming to OSHA/IBC guidelines.

JiffyRail Platform Guard Rail

The easy to install JiffyRail™ guard rail system guards open, exposed areas on mezzanine platforms and other elevated surfaces. It will help to eliminate fall hazards by providing strong, sturdy barrier protection.

Overhead Safety Gate

A Wildeck™ Overhead Safety Gate provide safe access to palleted material to and from a mezzanine or work platform.

Pallet Drop Zone Gate

Overhead safety gates provide safe access to palleted material to and from a mezzanine or work platform. When one side of the Drop Zone Gate is raised the other side closes, keeping your elevated areas protected at all times.

Pivot Safety Gate

A pivot safety gate will protect open areas on mezzanines, work platforms, balconies and racking systems during loading and unloading of product.

Powered Overhead Safety Gate

Roly™ Powered Overhead Safety Gates secure guardrail and doorway openings on mezzanines, work platforms, elevated platforms and rack picking modules.

Double Drop Safety Gate

When utilizing double drop safety gates mezzanine level personnel can access one pallet bay while a forklift operator at the ground level is accessing the other. One bay is always open at the mezzanine level for forklift operations and lifting.

Slide Gate

Industrial Sliding Gates allow for safe and easy loading and unloading of equipment and product from mezzanines and other elevated storage areas. The advantage of the sliding safety gate design over the swing safety gate is that it takes up less floor space, since it does not have to swing in to open. The are available in powered and non-powered versions.

Lift Gate

Mezzanine Lift Gates allow for openings of 6 feet to 8 feet wide on a mezzanine and are typically mounted to the mezzanine frame structure. Multiple lift gates can be placed side by side to create larger openings.

Rolling Slide Gate

Rolling Slide Gates are space efficient, making them an ideal gate for pick module operations and mezzanine/deck surfaces.

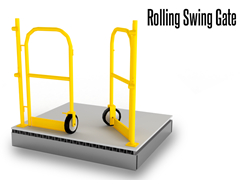

Rolling Swing Gate

Rolling swing gates offer a simple and cost effective solution for those instances when overhead space is limited.

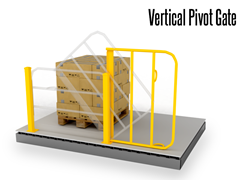

Vertical Pivot Gate

Vertical Pivot Gates provide a solution for areas lacking horizontal clearance space.

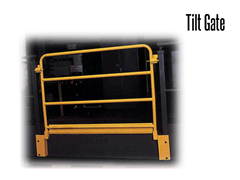

Tilt Gate

A tilt gate provides an extra measure of safety when workers are handling pallets of product on mezzanines.

Swing Gate

Swing gates allow easy and convenient opening and closing for mezzanine access.

Finger Gate

Finger gates provide a protective barrier at elevated work levels, such as mezzanines or pallet racking. It is commonly found on pallet flow racks and areas where gravity fed pallets are utilized.

NetGate Pick Module Safety Gate

The NetGate™ Pick Module Safety Gate allows users safe access to palletized materials on elevated pick modules and rack systems.

Impact Gate

Impact gates are designed to open and close during pallet load transfers and drop offs. They are ideal for forklift operations due to the minimal effort in the unload process.

Edge Alert™ Open Gate Alarm

The Edge Alert™ Open Gate Alarm signals an open gate with flashing LED lights and an audible alarm.

Edge Gard™ Folding Loading Dock Gates

The EdgeGard™ Folding Loading Dock Gate protects wider openings and minimizes required clearance heights.

Edge Gard™ Straight Loading Dock Gates

The Edge Gard™ Straight Loading Dock Gate is ideal for standard dock widths. They are durable, reliable and safe.