-

Conveyor Equipment

- Belt Conveyors >

- Powered Roller Conveyors >

- Gravity Roller Conveyors

- Conveyor Accessories >

- Stainless Steel and Food Grade Conveyor Systems >

- Extendable / Accordion Conveyors

- Vertical Conveyors

- Bulk Handling Conveyors

- Transfer and Merge Conveyors

- Overhead Conveyor and Monorail Conveyor Systems

- Custom Equipment

- Sortation Systems

- Ergonomic Equipment

- Mezzanines & Lifts

-

Packaging & Warehouse

- Pallet Flow Racking and Case Flow Racking Systems

- Gorbel Cranes and Monorails

- Guard Rail and Collision Awareness

- Safety Fencing & Machine Guards

- Palletizers

- Case Former / Case Erector

- Case Sealers >

- Conveyor Guarding

- Metal Detection Equipment

- Automatic Strappers

- Pallet Stackers / Pallet Dispensers

- Stretch Wrapping Equipment

- Modular Office

- Robotic Handling

- Industries Served

- About Us

Gravity Roller Conveyors

A gravity roller conveyor moves material and product without a motor power source, usually down an incline or on a flat surface with a person pushing the item across. Because of this, they are one of the most economical material handling solutions when used in the right application. They are designed to handle a wide range of sizes and weights of items, including boxes and cartons, which have firm bottoms.

Thomas Conveyor & Equipment Company offers a vast selection of gravity roller conveyors, both straight and curved. View all of these products below and click on each one for more information. Call us today to speak with an application engineer to get started on your design.

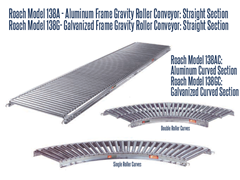

1/3-8” DIA. X 18 GA. Gravity Roller Conveyor (Roach Model 138A-138G)

Roach Model 138A-138G conveyors are typically mounted on a slight decline angle, therefore using gravity to assist product movement, especially for long distances. They can also be used in applications where the conveyor is level and operators can push the product along to its final destination, allowing for multiple workstations, if needed.

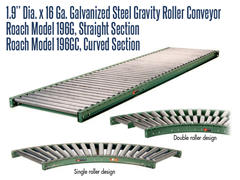

1.9” Dia. X 16 Ga. Galvanized Steel Gravity Roller Conveyor (Roach Model 196G)

The 1.9" diameter x 16 gauge galvanized steel straight (Model 196G) or curved gravity roller conveyor (Model 196GC) is designed to convey lightweight packages, cartons or totes. It also has a protective zinc coating to prevent rusting.

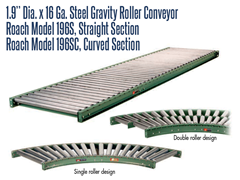

1.9” DIA. X 16 GA. Steel Gravity Roller Conveyor (Roach Model 196S)

A gravity conveyor moves the load without utilizing motor power sources, usually down an incline or through a person pushing the load along a flat conveyor. The Roach Model 196S/196SC 1.9" diameter x 16 gauge steel, straight or curved gravity roller conveyor transports products or work in process from one work area to another.

1.9” Dia. X 12 Ga. Gravity Roller Conveyor (Roach Model 192S)

The 1.9” diameter X 12 gauge gravity roller conveyor (Roach Model 192S/192SC) is ideal for applications that require an economical, non-powered means for conveying material. It has a 260 lb capacity per roller.

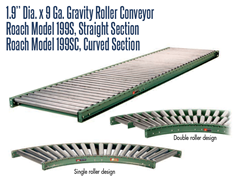

1.9” DIA. X 9 GA. Gravity Roller Conveyor (Roach Model 199S)

The 1.9" diameter x 9 gauge steel straight or curved gravity roller conveyor, Roach Model 199S, conveys product efficiently and economically.

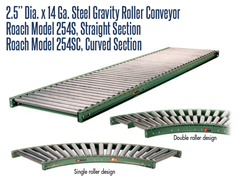

2-1/2” DIA. X 14 GA. Steel Gravity Roller Conveyor (Roach Model 254S)

A gravity roller conveyor is among the most common pieces of equipment found in many warehouses and manufacturing plants. The 2-1/2" diameter x 14 gauge steel, straight or curved gravity roller conveyor can be used as transportation for cartons, packages and/or pallets.

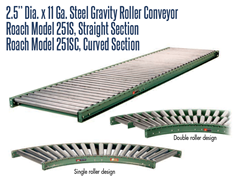

2-1/2” DIA. X 11 GA. Steel Gravity Roller Conveyor, Roach Model 251S

The Model 251S/251SC is a straight or curved structural steel gravity roller conveyor with a frame capacity of 3400 lbs. maximum distributed live load per 10’ section with supports at 10’ centers and 7500 lbs. at 5' centers. Roller capacity is 540 lbs per roller.

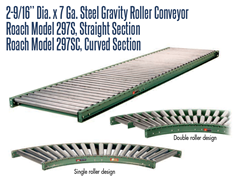

2-9/16” Dia. X 7 GA. Steel Gravity Roller Conveyor, Roach Model 297S

The Roach Model 297S is designed and constructed to convey those extra heavy loads that require a rugged dependable service. Applications include conveying extra heavy pallets, large castings, heavy structural steel products, and large coils of sheet metal.

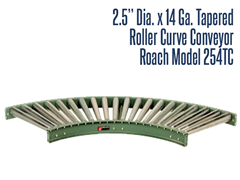

2.5” Dia. X 14 GA. Tapered Roller Curve, Roach Model 254TC

A 2-1/2” Dia. X 14 Ga. tapered roller curve conveyor can add to the versatility of straight conveyors. Curves provide smooth product flow with a minimum amount of pitch based on the weight and size of the product being conveyed.

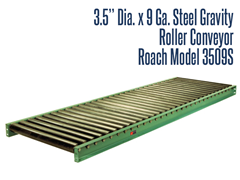

3-1/2” Dia. X 9 GA. Steel Gravity Roller Conveyor, Roach Model 3509S

3-1/2” Dia. X 9 Ga. Steel Gravity Roller Conveyor Roach Model 3509S is typically mounted on a slight decline angle, using gravity to assist product movement. Operators can also push the product along to the final destination.

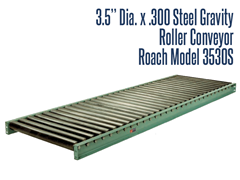

3-1/2” Dia. X .300 Steel Gravity Roller Conveyor, Roach Model 3530S

The 3-1/2” Dia. X .300 Steel Gravity Roller Conveyor Roach Model 3530S conveyor is a structural steel conveyor built to handle heavy duty pallets, drums, barrels, large coils of sheet metal and large castings.

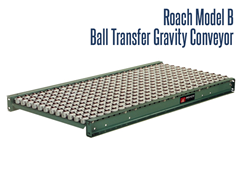

Ball Transfer Units, Roach Model B

Move boxes, packages, crates, etc. any direction, effortlessly using the Ball Transfer Units Roach Model B. Ball transfer tables are used at packaging and assembly stations where product needs to be rotating or moved in more than one direction.

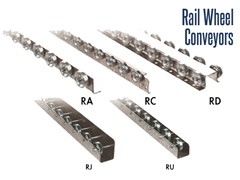

Roach Rail Wheel Conveyor

Roach Rail Wheel Conveyors are economical means of conveying products on the floor or within flow racks. The rails are mounted to convey unit loads utilizing an arrangement of two or more rail conveyors mounted parallel.

Roach Model WA & WS Aluminum and Zinc Plated Gravity Wheel Conveyor/Conveyor Curves

The Roach WA & WS Gravity Wheel Flexible Conveyor is a durable, portable gravity conveyor that can instantly set up a conveyor line for shipping, receiving, assembly, and packaging on plant floors or back rooms.