-

Conveyor Equipment

- Belt Conveyors >

- Powered Roller Conveyors >

- Gravity Roller Conveyors

- Conveyor Accessories >

- Stainless Steel and Food Grade Conveyor Systems >

- Extendable / Accordion Conveyors

- Vertical Conveyors

- Bulk Handling Conveyors

- Transfer and Merge Conveyors

- Overhead Conveyor and Monorail Conveyor Systems

- Custom Equipment

- Sortation Systems

- Ergonomic Equipment

- Mezzanines & Lifts

-

Packaging & Warehouse

- Pallet Flow Racking and Case Flow Racking Systems

- Gorbel Cranes and Monorails

- Guard Rail and Collision Awareness

- Safety Fencing & Machine Guards

- Palletizers

- Case Former / Case Erector

- Case Sealers >

- Conveyor Guarding

- Metal Detection Equipment

- Automatic Strappers

- Pallet Stackers / Pallet Dispensers

- Stretch Wrapping Equipment

- Modular Office

- Robotic Handling

- Industries Served

- About Us

Mechanical Lifts - Vertical Reciprocating Conveyors (VRCs)

Mechanical vertical lifts or Vertical Reciprocating Conveyors (VRCs) provide a safe, easy and cost-effective solution for the transport of staff and product from one elevation to another. Vertical lifts are safer than a forklift and can handle much heavier loads. They are faster and offer a wide variety of flexibility in carriage size, capacity and traffic patterns.

They also offer a great deal of versatility and dependability for high speed and multi-level transport to mezzanines, rack storage systems or upper floor levels.

VRC Benefits:

|

Typical Application Guidelines

|

|||||||||||||||||||||||||

Thomas Conveyor offers both Mechanical and Hydraulic VRCs. We are here to assist you with your lift requirements! Contact our team today to get started.

Mechanical Straddle VRC

The Mechanical Straddle VRC showcases a 2 straddle configuration allowing the choice of a "C" or "Z" loading or unloading pattern.

Mechanical Cantilever VRC

The Mechanical Cantilever VRC showcases a 2 post configuration allowing the choice of a "C", "Z" or 90° loading or unloading pattern.

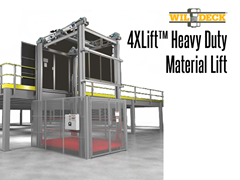

4XLift™ Heavy Duty Material Lift

4 Post Heavy Duty Material Lift : The new standard for heavy duty elevated lifting. This unit can handle up to 30,000 lbs.

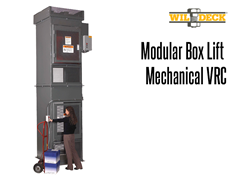

Modular Box Lift

The Modular Box Lift allows users to move parts, boxes, totes and carriers.

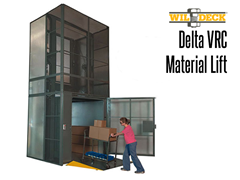

Delta Vertical Reciprocating Conveyor Material Lift

The Delta VRC offers the lower price of a hydraulic VRC while integrating the advantages of a mechanical lift.

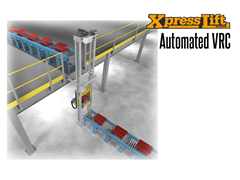

XpressLift™ Automated VRC

The XpressLift™ VRC integrates high speed vertical lifting into your automated conveyor system. It can help to achieve increased process efficiency through the automated vertical transfer of materials between conveyor production levels.

FlexLoader™ Material Conveyor System

A FlexLoader Material Conveyor System integrates a Wildeck VRC with Safety Gates and an automated, flush mount conveyor system into one work platform designed to maximize space usage.

V-Lift™ Hydraulic Vertical Conveyor

Best suited for single-level material handling, the V-Lift™ Hydraulic Vertical Conveyor is a powerful, cost effective, and space saving solution for all of your industrial lifting needs.

Custom Hydraulic VRCs/Lifts

Vertical Reciprocating Conveyors (VRCs) also known as Material Lifts or Freight Lifts can be customized to lift your product to integrated mezzanines, multi-level warehousing, catwalks, racking in an archival facility or any other area needing material elevation. With hundreds of configurations possible, let our experienced Automation Engineers design a custom solution for you.

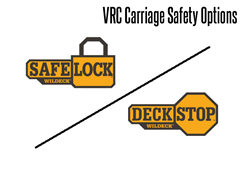

VRC Carriage Safety Options

Carriage safety options such as SafeLock and DeckStop are available for VRCs and provide an additional level of safety protection.

VRC Lift Control Systems

Lift safety controls help to protect materials and products going into your VRC lift and the lift itself. They also help protect against jams when materials shift during the lift process and keep unauthorized users from operating the lift mechanism.

VRC Carriage Gates and Entrance Gates

Safety gates come in a wide variety of configurations and are designed to maximize safety and performance. VRC gates feature both floor level entrance gates and carriage mounted gates. CargoLok™ Gates are designed to secure heavy carts or rolling loads during transport.

Lift Carriages, Carriage Guarding and Carriage Safety Options

Thomas Conveyor & Equipment offers a wide variety of Lift/VRC Carriages, carriage guarding and carriage safety options, including ArmorCar™ Carriages, CargoLok™ carriage guarding and Safelock and DeckStop safety systems.

VRC Lift Entrance Ramps

VRC material lift carriages have a variety of ramp mount options to choose from, based on the configuration of your VRC. Some of the options include standard, winged or pit-mounted.