-

Conveyor Equipment

- Belt Conveyors >

- Powered Roller Conveyors >

- Gravity Roller Conveyors

- Conveyor Accessories >

- Stainless Steel and Food Grade Conveyor Systems >

- Extendable / Accordion Conveyors

- Vertical Conveyors

- Bulk Handling Conveyors

- Transfer and Merge Conveyors

- Overhead Conveyor and Monorail Conveyor Systems

- Custom Equipment

- Sortation Systems

- Ergonomic Equipment

- Mezzanines & Lifts

-

Packaging & Warehouse

- Pallet Flow Racking and Case Flow Racking Systems

- Gorbel Cranes and Monorails

- Guard Rail and Collision Awareness

- Safety Fencing & Machine Guards

- Palletizers

- Case Former / Case Erector

- Case Sealers >

- Conveyor Guarding

- Metal Detection Equipment

- Automatic Strappers

- Pallet Stackers / Pallet Dispensers

- Stretch Wrapping Equipment

- Modular Office

- Robotic Handling

- Industries Served

- About Us

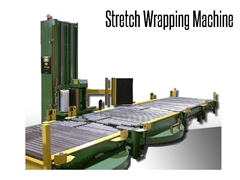

Stretch Wrapping Equipment

Stretch film is used to wrap products on pallets, securing them to each other and the pallet to improve stability and create a unit load. It can also bundle smaller items, reducing product loss, discouraging tampering, and minimizing worker injuries.

Stretch wrapping also provides efficient handling and storage for unit loads, aids in dust and moisture protection, can extend the shelf life of certain items, and provides a degree of protection from the sun.

There are several types of stretch wrappers available: manual or hand wrappers; semi-automatic wrappers, including turntable, orbital, and rotary arm wrappers; and fully automatic wrappers. Automatic wrappers feature a conveyor system for automatic loading and mechanisms to apply, seal, and cut the film. These automatic systems are available in turntable, rotary arm, and rotary ring formats..

Thomas Conveyor & Equipment can provide your operation with a consultation to determine which stretch wrapping equipment system will provide the optimal functionality for your business. We can even provide custom wrapping solutions and other equipment to meet your needs. Call us today for a free consultation.

Stretch Wrapping Machines

Stretch wrappers are essential for any business wrapping more than 10-15 pallets a day. By utilizing a stretch wrapper machine, you can significantly reduce labor costs and achieve an immediate return on investment. These machines often pay for themselves within months by freeing up employees for other tasks and significantly reducing stretch film usage.