Challenge

The customer needed an industrial steel work platform (mezzanine) to create additional work / storage space and vital access to hard-to-reach areas of equipment for maintenance. This customer needed an irregularly shaped mezzanine because there were doorways and hallways that could not be blocked with columns.

Solution

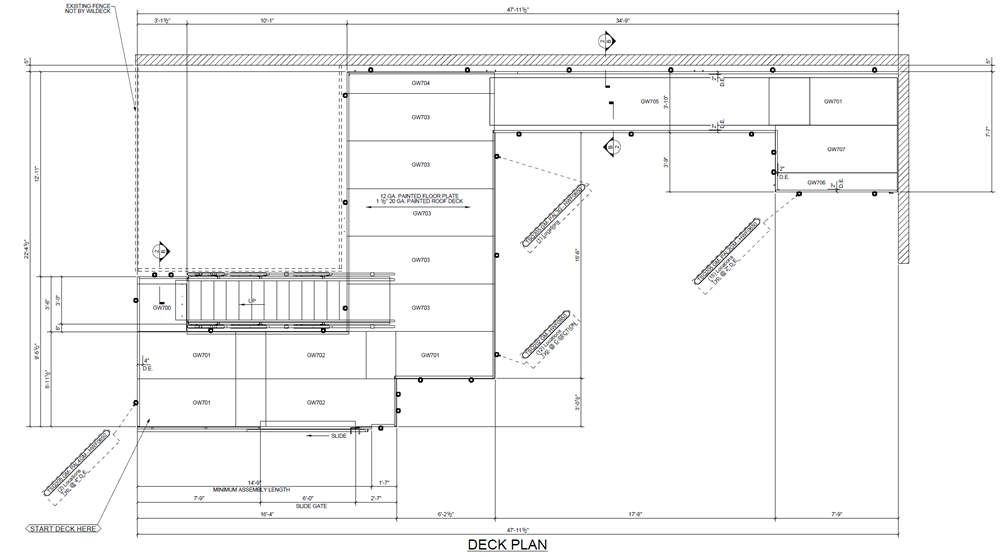

As a Thomas Conveyor project engineer, Owen visited with the customer and took laser measurements of the space and prepared an AutoCAD.DWG to replicate the field drawing. Owen presented the customer with a quote and concept drawing. Once the project was sold, we provided an engineered approval drawing to the customer for review, prior to fabrication.

Owen made one more visit with the customer to verify the dimensions. The customer reviewed the drawing and signed it – marked approved as drawn. The order then went into fabrication. Once the order was fabricated, shipped, and delivered, my installation team erected and anchored the irregularly shaped mezzanine into its tight space. The benefit of working with a Thomas Conveyor project engineer is having one contact to manage the whole project from inquiry to install.

The industrial steel work platform was constructed with c-sections, wide flange beams, and 6” x 6” columns with 12” x 12” base plates. The decking consisted of the base 20-gauge 1.5” deep painted white type B roof deck and surface 12-gauge floor plate painted black. The structure is rated as 125 psf (pounds per square foot). We supplied a 2-rail square tube guard rail and kickplate around all sides of the mezzanine. Also included was a 6’ wide 2-rail slide gate for pallet access to safely load or unload pallets to or from the mezzanine deck. Each mezzanine has different requirements, and the structure can be engineered to your specifications.

Results

A mezzanine is the best solution to fully optimize your existing space. You can gain additional square footage without having to move your operation to a larger building or rent out the space next door. Here are several more mezzanine uses:

- A mezzanine can be used as a storage deck to store materials.

- Conveyors can be installed on the mezzanine and integrate with conveyors down on the ground.

- An in-plant office can be installed on a mezzanine deck to increase office space.

- The warehouse manager can use the mezzanine as an observation deck.

- The mezzanine can be a catwalk between two areas to provide safe and efficient access for personnel.

- A mezzanine provides access to equipment for operations and maintenance.

- Can store racks and shelves as a storage solution. The framing components can be designed with brackets to accept new modular sections of mezzanine when your storage needs grow.

- Mezzanines have also been used for live televised broadcasts.

Manufacturing and engineering of the industrial steel work platforms is local here in Wisconsin, which leads to lower freight costs if the project is located in the Midwest. We use high quality American steel, and we’re made in the USA.

Have a project? Contact a project engineer with Thomas Conveyor at 708-449-2100.

Our final addition to this pack station was Stainless Steel Shelving, both on top of the upper conveyor for pre-erected case storage, and a shelving unit in front of the workers to support newly erected cases the workers were utilizing to pack the bagged product inside. These shelving units were designed to be easily separated in case the units were moved to different parts of the facility.

Our final addition to this pack station was Stainless Steel Shelving, both on top of the upper conveyor for pre-erected case storage, and a shelving unit in front of the workers to support newly erected cases the workers were utilizing to pack the bagged product inside. These shelving units were designed to be easily separated in case the units were moved to different parts of the facility.

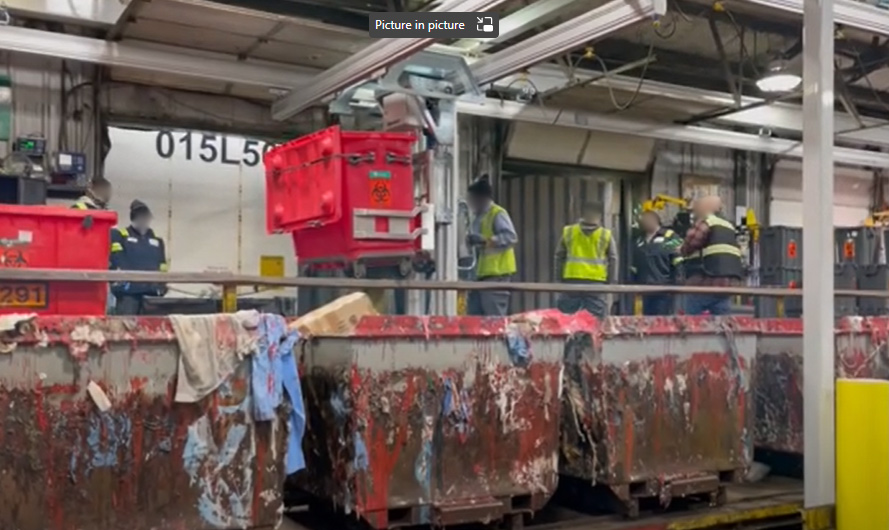

Because this industry is ever changing and looking for continuous improvement opportunities, the decision was made to use a range of larger containers.

Because this industry is ever changing and looking for continuous improvement opportunities, the decision was made to use a range of larger containers. The operation of the unit is simple. Once a container has been identified for dumping an operator grabs on to the MechLift unit and manually moves it towards and positions the end effector tooling around it. Then the tooling, which is electrically driven, is engaged by hitting a button to activate the closing feature whereby grasping and holding the outside of the container.

The operation of the unit is simple. Once a container has been identified for dumping an operator grabs on to the MechLift unit and manually moves it towards and positions the end effector tooling around it. Then the tooling, which is electrically driven, is engaged by hitting a button to activate the closing feature whereby grasping and holding the outside of the container. The conveyor will receive boxes with taped bottoms, and open tops with a bag of liquid food product inside the box at 30” infeed top of belt elevation at a rate of four boxes per minute. The product is conveyed up the incline to nose over at 46” top of belt elevation at the discharge end. The supports are hygienic, adjustable swivel locking casters, with +/-1.5” height adjustment.

The conveyor will receive boxes with taped bottoms, and open tops with a bag of liquid food product inside the box at 30” infeed top of belt elevation at a rate of four boxes per minute. The product is conveyed up the incline to nose over at 46” top of belt elevation at the discharge end. The supports are hygienic, adjustable swivel locking casters, with +/-1.5” height adjustment. The product is guided with UHMW guard rail. The frame is constructed of 300 series stainless steel and is fully welded. We utilize hygienic construction methods for high care applications. The carry way and return rollers are made of white UHMW. This conveyor can be dis-assembled and re-assembled for cleaning without the use of any tools (toolless removal). Included is a washdown NEMA 4x / IP66 variable frequency drive (VFD), side mounted on a support arm, pre-wired to the IP69K stainless steel motor and gear reducer, and an 8’ long loose end cord is supplied for your electrical input. The side frame also has access slots for easy cleaning. Safety is also important, and we supplied a pre-wired and mounted maintained emergency stop switch on each side.

The product is guided with UHMW guard rail. The frame is constructed of 300 series stainless steel and is fully welded. We utilize hygienic construction methods for high care applications. The carry way and return rollers are made of white UHMW. This conveyor can be dis-assembled and re-assembled for cleaning without the use of any tools (toolless removal). Included is a washdown NEMA 4x / IP66 variable frequency drive (VFD), side mounted on a support arm, pre-wired to the IP69K stainless steel motor and gear reducer, and an 8’ long loose end cord is supplied for your electrical input. The side frame also has access slots for easy cleaning. Safety is also important, and we supplied a pre-wired and mounted maintained emergency stop switch on each side. We have a modern manufacturing facility that takes pride in producing high quality items at a great value to service your needs. We strive to keep your work environment efficient and clean. Our hygienic conveyor line is fabricated and made in the great state of Illinois, USA. Being in the center hub of the Midwest gives our customers more economic freight options due to the logistics of our location. Our engineers are fully capable of understanding your complex project needs and can be of great resource to you and your company for projects designed to promote growth for your company and improve your operations.

We have a modern manufacturing facility that takes pride in producing high quality items at a great value to service your needs. We strive to keep your work environment efficient and clean. Our hygienic conveyor line is fabricated and made in the great state of Illinois, USA. Being in the center hub of the Midwest gives our customers more economic freight options due to the logistics of our location. Our engineers are fully capable of understanding your complex project needs and can be of great resource to you and your company for projects designed to promote growth for your company and improve your operations. A major Biopharmaceutical Company approached Thomas Conveyor & Equipment Company to provide a storage solution in one of their laboratory equipment facilities. They were looking for a cost effective, safe and easy way to move and store mobile lab equipment.

A major Biopharmaceutical Company approached Thomas Conveyor & Equipment Company to provide a storage solution in one of their laboratory equipment facilities. They were looking for a cost effective, safe and easy way to move and store mobile lab equipment. The mezzanine was designed with a capacity of 250 lbs. PSF as some of the equipment was quite heavy.

The mezzanine was designed with a capacity of 250 lbs. PSF as some of the equipment was quite heavy. Thomas Conveyor & Equipment provided all the design, approval drawings, PE sealed drawings and structural drawings along with complete mechanical and electrical installation. Truly a one-stop shop.

Thomas Conveyor & Equipment provided all the design, approval drawings, PE sealed drawings and structural drawings along with complete mechanical and electrical installation. Truly a one-stop shop. Our design for the ceiling high fence panels allowed us to tie into the building’s ceiling joists as a top anchor that allowed us to control sway and maximize our wall stability. This gave the customer the exact height requirement they had asked for without requiring an extra large baseplate for each of our fence posts.

Our design for the ceiling high fence panels allowed us to tie into the building’s ceiling joists as a top anchor that allowed us to control sway and maximize our wall stability. This gave the customer the exact height requirement they had asked for without requiring an extra large baseplate for each of our fence posts.