-

Conveyor Equipment

- Belt Conveyors >

- Powered Roller Conveyors >

- Gravity Roller Conveyors

- Conveyor Accessories >

- Stainless Steel and Food Grade Conveyor Systems >

- Extendable / Accordion Conveyors

- Vertical Conveyors

- Bulk Handling Conveyors

- Transfer and Merge Conveyors

- Overhead Conveyor and Monorail Conveyor Systems

- Custom Equipment

- Sortation Systems

- Ergonomic Equipment

- Mezzanines & Lifts

-

Packaging & Warehouse

- Pallet Flow Racking and Case Flow Racking Systems

- Gorbel Cranes and Monorails

- Guard Rail and Collision Awareness

- Safety Fencing & Machine Guards

- Palletizers

- Case Former / Case Erector

- Case Sealers >

- Conveyor Guarding

- Metal Detection Equipment

- Automatic Strappers

- Pallet Stackers / Pallet Dispensers

- Stretch Wrapping Equipment

- Modular Office

- Robotic Handling

- Industries Served

- About Us

Stainless Steel Types, Finishes, Chemical Finishes and Welds

The various types of stainless steel details are an important aspect of food and pharmaceutical handling applications. Understanding the material finishes, weld types and design aspects will assist you in understanding the equipment selection process with your Thomas Conveyor Automation Engineer.

Why use Stainless Steel for Food Processing?

The following are just some of the reasons why stainless steel has been incorporated by food service companies:

- It's Easy To Clean

Other materials, such as wood or plastic, have grooves or openings where bacteria can invade and grow. Stainless steel is smooth and doesn't provide a place for bacteria to hide, allowing it to be easily cleaned. When cleaning stainless steel, it is important to always use a food-grade stainless steel cleaner. - It's Durable:

Steel is one of the most durable metals on the market. Not only is it less prone to physical damage, but it is also resistant to corrosion, as well as wear and tear related to aging. While other metals have to be maintained during use, stainless steel will likely need fewer professional repairs. - Stainless Steel has a Non-Reactive Surface

Stainless steel is a non-reactive metal, which means that you can use it to cook or process foods that are acidic, such as citrus, tomatoes, and vinegar. Other metals, like aluminum and iron, are reactive. Processing acidic foods on these metals may affect the flavor of the food, typically adding a metallic flavor, and can damage the surface of the metal. - It's Chemical-Resistant/Corrosion Resistant

While various stainless steel grades will behave differently, most are generally resistant to chemicals. This means that even the heaviest bleaches and other cleaners can be used on the surface without causing damage. Stainless steel is also especially resistant to corrosion and rusting compared to other metals, which makes it perfect for use in the kitchen. Food-grade stainless steel is often used for kitchen equipment, which can be costly to install. But, because most grades of stainless steel are highly corrosion-resistant, the equipment does not need to be replaced as frequently. - Stainless Steel is Heat Safe:

This is an especially useful property when working with heavy machinery. Stainless steel is able to withstand high temperatures and pressures without morphing or altering. It will also hold its shape in heat conditions. - Easy Fabrication:

As for the fabrication of stainless steel, there are many ways that it can be manipulated. It can be cut, welded, and formed quite easily, especially with more current metal-working techniques. This makes it suitable to make small tools as well as large appliances.

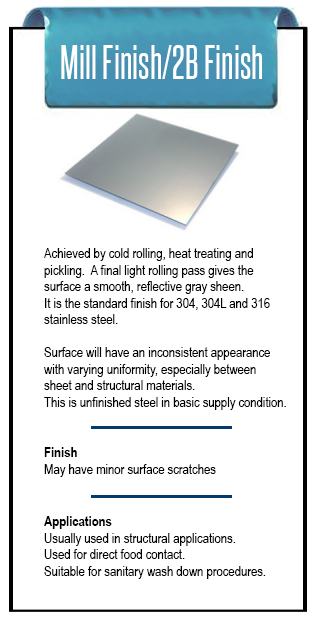

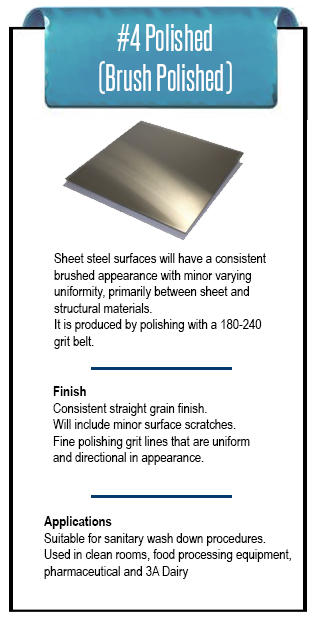

Stainless Steel Finishes

|

|

|

Chemical Finishes

|

|

|

|

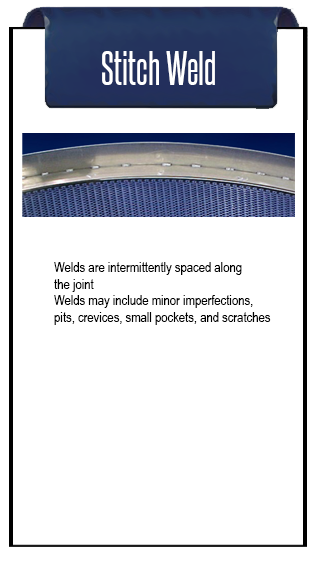

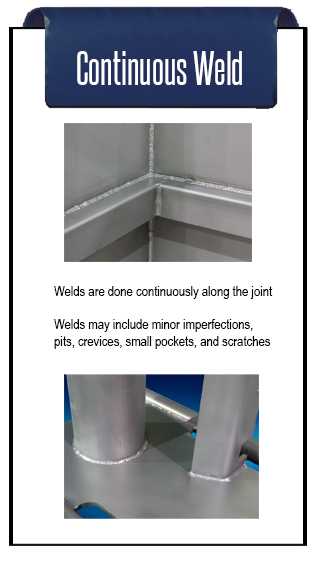

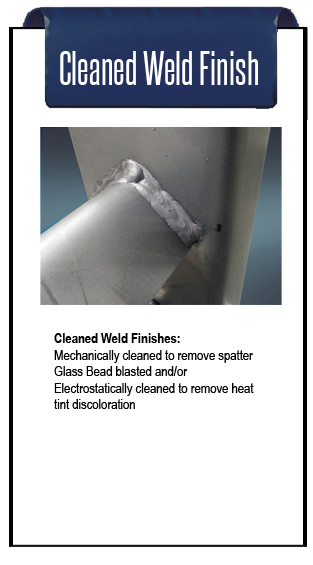

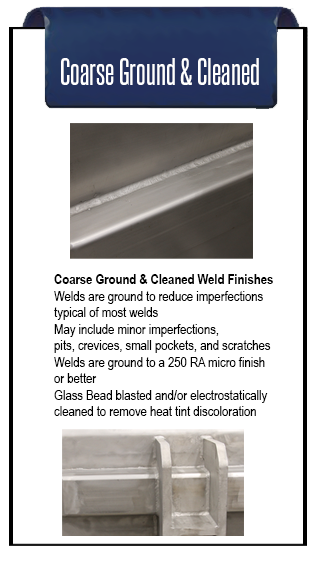

Welds and Weld Finishes

|

|

|

|

For more information on Stainless Steel surfaces, processes or applications for your systems operation, please contact a Thomas Conveyor & Equipment Automation Engineer at 800 220 0086 or click on the Contact Us button above.