VRC gates provide an extra measure of safety and performance on VRC lifts. They can be either floor level entrance or carriage mounted. CargoLok™ gates provide an additional level of security when working with heavy carts or rolling loads.

Safety gates come in a wide variety of configurations and are designed to maximize safety and performance. VRC gates must meet applicable codes and are equipped with elevator style electro-mechanical interlock devices for exceptional performance and endurance. VRC gates feature both floor level entrance gates and carriage mounted gates. CargoLok™ Gates are designed to secure heavy carts or rolling loads during transport.

Carriage Gates CargoLok™ Gates Entrance Gates

Vertical Reciprocating Conveyor Carriage Gates

Standard VRC carriages use snap chain(s) across the loading and unloading ends of the carriage. There is a wide variety of options to customize your carriage mounted gates, and when combined with carriage mounted guarding materials, can provide a greater degree of protection for your material loads.

Carriage mounted gates options include:

- CargoLok™

- Diagonal Drop Bars

- Swing Gates

- Heavy Duty Lift Rails

- Vertical Lift Gates

- Roll-up doors

CargoLok™ Locking Material Lift Gate

The CargoLok™ bi-parting locking safety carriage gate for VRCs is a fitting solution for curbing movement of heavy carts or other rolling loads placed in a VRC carriage. CargoLok™ features steel reinforced construction, combined with a heavy duty sliding deadbolt which secures the carriage gate.

The CargoLok™ bi-parting locking safety carriage gate for VRCs is a fitting solution for curbing movement of heavy carts or other rolling loads placed in a VRC carriage. CargoLok™ features steel reinforced construction, combined with a heavy duty sliding deadbolt which secures the carriage gate.

The easy to use deadbolt handle is located at the top of the gate to allow operators easy access to engage the VRC gate lock. A "Gate Locked" switch confirms that the gate is closed with the deadbolt enabled before the VRC can operate. An optional audible alarm is available to alert operators to lock the deadbolt prior to operation.

VRC System Entrance Gates

Thomas Conveyor & Equipment offers a variety of VRC gates to meet the needs of your operation. Combined with safety guarding products, the proper use of a VRC they can increase safety, aid production and minimize accidents at your facility.

All of our VRCs, gates and guards meet applicable codes and are equipped with ‘elevator style’ electro-mechanical door locks for unparalleled performance and extreme durability.

All conveyors are required by ANSI/ASME B20.1 code to have enclosures and gates at each stop or landing, but each application should be examined for adherence to national, state and local codes.

Specifications:

- Meets ANSI/ASME B20.1 Safety Standards

- Rigid Steel Construction

- Gate panel is Constructed of Flattened Expanded Metal Tube and Angle Framing

- Feature Heavy Duty, Maintenance Free Hinges

- Gate Panel is Secured Using an Electro-Mechanical Interlocking Device

- No Solenoids to Fail

Single Panel Swing Gate, Left or Right Hinged

- Available In Left Or Right Swing Direction (Hinged On Left Or Right)

- Requires 8" Vertical Clearance At Either Level

- Ships Disassembled With Anchors And Assembly Hardware Provided

- 6 Ft. Maximum Width Recommended

Text

Text

Bi-Parting Swing Gate

- Requires 8' Vertical Clearance At Either Level

- Best Used Where Space Is At A Premium (10 Ft Max Width Recommended)

- Ships Disassembled With Anchors And Assembly Hardware Provided

Text

Text

Single Panel Vertical Gate

- Requires 14'-4" Vertical Clearance at Either Level

- Heavy Duty Roller Chain and Sprockets

- Best Used Where Aisle Space Is Minimal With No Height Restrictions (12-Ft Max. Width Recommended)

- Ships Disassembled with Anchors and Assembly Hardware Provided

- Powered Vertical-Acting Gate Available for Faster Material Loading

- Wall-Mounted Pushbutton or Pendant Gate Motor Control

- PLC Interface Available for Automated Gate Control During Conveyor Loading & Unloading

Bi-Panel Vertical Acting Gate

- Requires 11'-6" Vertical Clearance at Either Level

- Heavy Duty Roller Chain and Sprockets

- Best Used Where Aisle Space is Minimal But Height is Available (12-Ft Max. Width Recommended)

- Ships Disassembled with Anchors and Assembly Hardware Provided

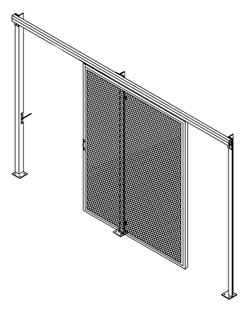

Horizontal Slide Gate

- Requires 8" Vertical Clearance at Either Level

- Best Used with a Large Amount of Aisle Space

- Ships Disassembled With Anchors and Assembly Hardware Provided (Wiring By Others)

TEXT

TEXT

Thomas Conveyor & Equipment provides state-of-the-art engineering, automation, and controls integration solutions for manufacturing, industrial, and commercial applications. For more information on any of the VRC Gate configurations shown above, please contact a Thomas Conveyor & Equipment Automation Engineer at 844 220 0086 or click on the Contact Us button above.