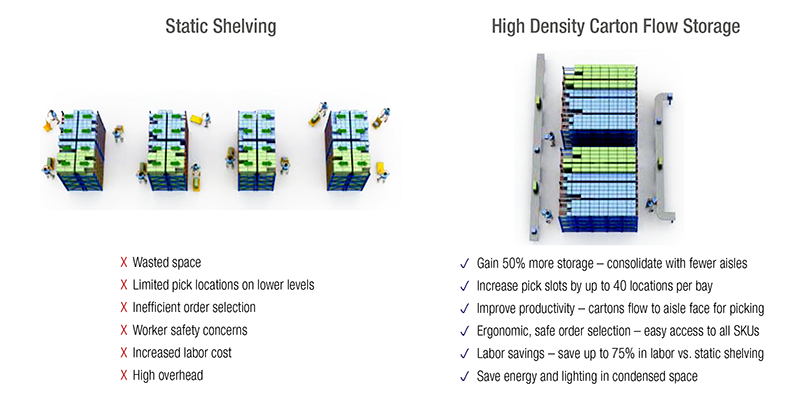

We offer a wide variety of carton flow products, designed to handle frequent product mix changes. The racking systems are custom designed for your specific application requirements and are adaptable to roll formed or structural racking.

Gravity-fed carton flow pallet racking is an affordable way to save space, unify order picking activity and increase pick positioning within your existing space. Totes are fed into storage lanes from one aisle and flow to the opposite aisle for full and split-case picking, separating picking and replenishment. Carton Flow can be used as a stand-alone system or integrated with conveyor, pick-to-light and multi-level pick modules.

Varying Carton Widths

Dyna-Flo

Flexible, Full Bed Carton Flow Racking for Variable Sized SKUs

Dyna Flo features a bed of staggered polypropylene wheels ideal for variable sized SKUs and applications needed frequent re-slotting. 12" - 16" sections fit into existing pallet racking allowing for easy of use and a productive flow system.

Advantages:

- Easily drops into existing pallet rack

- Full wheel bed accommodates cartons of all sizes and shapes

- Durable wheel and axle assembly

- Simple, easy product reprofiling

- Consolidates and increases pick slots

Specifications:

- Plastic polypropylene staggered wheel

- 12″-16″ wide sections – (6) 16″ cover 96″ beam

- Available in 1″, 2″ and 3″ centers

- Adjustable full-lane dividers

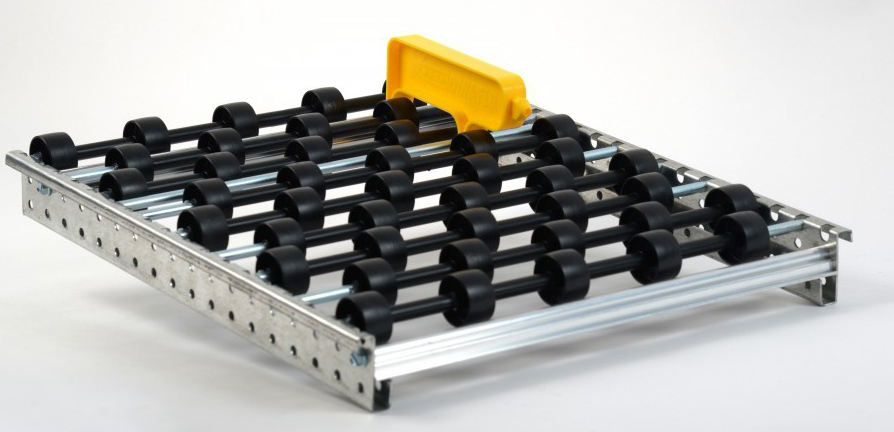

Dyna-Flo HD (Heavy Duty)

Heavy Duty, Reinforced Dyna-Flo for Tougher Applications

Dyna-Flo HD is the solution for challenging package and carton flow requirements. Its larger, 1.9” polypropylene wheel with reinforced spokes provides greater capacity, wheel coverage and better flow for heavy, larger carton applications.

Product slotting and reprofiling is easy with the full-width wheel bed design which accommodates cartons of varying dimensions on each shelf. Lane guides and dividers can be quickly added or relocated to adjust carton sizes and to assist in faster SKU identification.

Dyna-Flo HD carton flow is a common application in retail, food, beverage, manufacturing and e-commerce distribution centers.

Dyna-Flo HD uses higher side rails which adds capacity without the need for an interior support beam, providing additional vertical clearance between shelf beams.

Advantages:

- Easily drops into existing pallet rack

- Full wheel bed accommodates cartons of all sizes and shapes

- Durable wheel and axle assembly

- Simple, easy product reprofiling

- Consolidates and increases pick slots

Specifications

- 1.9″ polypropylene staggered skate wheel

- 50 lb. sq. ft. capacity per 8 ft. unsupported length

- 12″-16″ wide sections – (6) 16″ cover 96″ beam

- Available in 2″ and 3″ centers

- Adjustable full lane dividers

- Optional order picking tilt tray

Dyna-Deck

Easy Drop In Repair System

Dyna-Deck is a replacement system for damaged case flow rails and wheels. Heavy, abuse resistant low profile tracks drop easily into existing carton flow shelves, providing full wheel coverage for all carton shapes and sizes.

Advantages:

- Retrofits/replaces any existing carton flow shelf

- Full wheel bed accommodates a variety of cartons, cases and totes

- Ideal for frequent inventory/SKU changes

- Infinitely adjustable, snap-on entry guides

Specifications:

- 1 1/2″ to top of roller

- 1 3/8″ polypropylene wheels

- 12″& 16″ width tracks – (6) 16″ tracks used for 96″ clear bay

- 1″, 2″ or 3″ roller centers

Rack-Trak

Drop In Carton Flow Tracks for Pallet Rack

Rack-Trak quickly converts pallet racking into a gravity flow system with wheeled tracks that easily drops onto stepbeams. Self-tracking lane assemblies are available in custom rail spacing configurations to meet all application requirements.

Advantages:

- Quickly convert pallet rack to carton flow

- Customizable for rail spacing, density and load capacity

- Adjustable end-stops, ideal for step beams

- Self-tracking for all load weights

- Custom guide rails available

Specifications:

- Durable plastic polypropylene wheels

- Fully adjustable rail spacing

- Staggered wheel patterns available to flow cartons as small as 2.5” x 2.5”

- Easy to handle sections up to 15’

- Adjustable full-lane dividers

Accessories for Carton Flow Racking

Carton flow systems can be equipped with accessories to help support the functionality of the racking system.

-

Tilt trays added to the pick-side enhance picking efficiency, accuracy and ergonomics. Customized in both length and width for a perfect fit in your system.

-

Impact trays installed on the load (charge) side protect the carton flow wheels from abuse of heavy inventory. Trays sit flush with the flow bed to easily slide product onto the wheels once placed in the lane.

-

Lane dividers, available in both partial and full-length, keep SKUs separated to increase both pick speed and accuracy. Snap-on lane dividers are perfect for fast inventory changes and reconfiguring

For more information on Carton Flow Racking or for a carton flow racking consultation, please contact a Thomas Conveyor & Equipment Automation Engineer at 844 220 0086 or click on the Contact Us button above.