Work Station Bridge cranes cover rectangular work areas, while monorail systems can be used to move loads along a linear path, cover various work area shapes, or to link work areas together.

Work station bridge cranes and monorails can be used singularly or can be modified to create complete systems with the addition of extra monorail tracks, curves, and transfers.

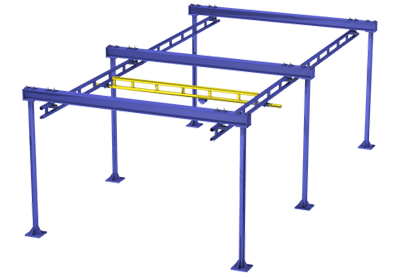

Free Standing Bridge Crane

Free Standing floor supported systems do not put stress on the building's overhead structure. Installation is straight forward, and cranes are easy to relocate in the future. Free Standing systems require a reinforced concrete floor of at least 6 inches.

- Capacities from 150 to 4000 lbs.

- Rectangular coverage with up to 34’ bridge and 124’ runway standard

- Standard support distances of 20', 25', and 30' feet.

- Easy to move and position loads

- Modular design for greater flexibility

- Doesn't require an existing support structure

Features

- Enclosed track, easy movement, long life

- Rigid runways, superior load positioning: no movement or “crab-walking” of the bridge

- Ease of Installation: Installs on any standard 6" concrete floor

- Smooth rolling surface, easier movement of bridge and trolleys

- Multiple track profiles and spanning capabilities: Adaptable, flexible, and cost competitive

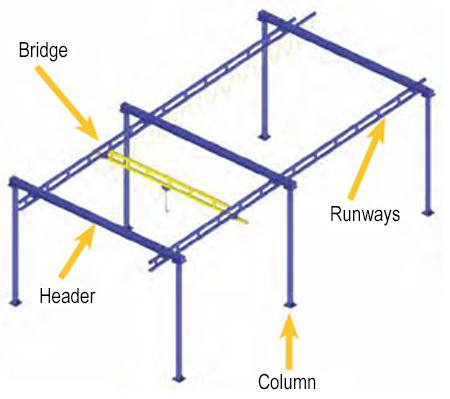

Work Station Cranes:

Bridge: The bridge is the only part of the work station crane in motion. It supports the lifting device and facilitates movement of the load along the Y and X axis. Bridges can be up to 34' long and are available in steel or aluminum.

Runways: the bridge's end trucks ride within the track of the crane's runways, which determine the overall coverage area of your work station crane. The track used for runways can be spliced together to span distances.

Column (Free Standing Only): The column are the "legs" of a freestanding work station crane. They are bolted to the floor and support the columns and the runways. The distance between columns is determined by your crane's overall capacity and the type of track.

Header (Free Standing Only): The work station crane system header is made of back to back "C" channel, which allows for easy connections to the runway hanger support hardware.

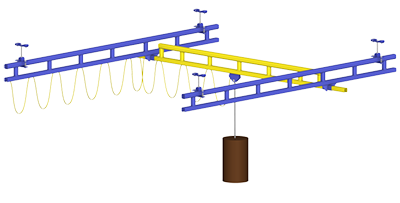

Ceiling Mounted Bridge Crane

With ceiling mounted bridge systems, the supporting steel does not interfere with handling operations. Ceiling mounted systems require a building with an adequate overhead structure to hang the crane.

- Capacities from 150 to 4000 lbs

- Rectangular Coverage with up to 34’ bridge and 124’ runway standard

- Standard support distances of 20', 25', and 30'.

Features

- Enclosed track, ease of movement and long life

- Rigid runways and superior load positioning: no movement or “crab-walking” of the bridge

- No support structures so work areas are kept clear of obstructions

- Smooth rolling surface, easier movement of bridge and trolleys

- Multiple track profiles and spanning capabilities: adaptable, flexible, and cost competitive

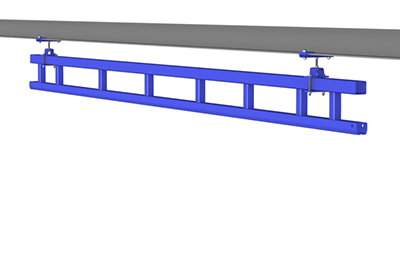

Monorails

- Capacities from 150 to 4000 lbs

- Linear movement

- Modular designs provide ultimate flexibility

- Can be integrated into a total system with extra track, curves, interlocks and switches

Features

- Steel or Aluminum track

- Free Standing options available contact customer service

- Enclosed track, easy movement and long life

- Ease of Installation

For more information on Gorbel™ Ceiling Bridge Cranes and Monorails, please contact a Thomas Conveyor & Equipment Ergonomic Automation Engineer at 844 220 0086 or click on the Contact Us button above.