Every project is different, and Thomas Conveyor & Electric’s extensive and varied experience is our strongest asset as your automation partner. We have the experience and technical knowledge to help you obtain the best fit when obtaining a lift control system for your VRC lift.

Increase your VRC’s electrical control and material handling efficiency with products such as AutoSenz™ and LiftLok™. Thomas Conveyor can provide you with a complete customized material lift system that is either manually controlled, regulated by your conveyor controls, or is fully automated, with the controller handling both the material lift and portions of your conveyor system.

We offer the following control systems:

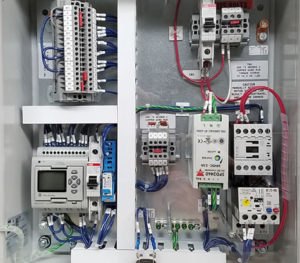

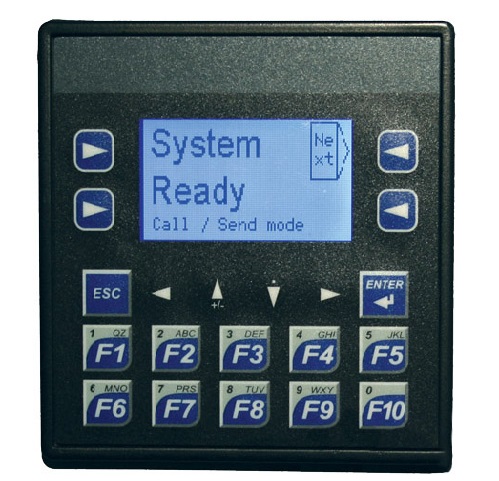

SmartControl™ (Mechanical VRCs)

The SmartControl™ system for mechanical VRCs provides operators with advanced safety attributes that will keep the lift operating smoothly.

- Perceptive digital interface and audible signals allow the operator to monitor the lift status and identify fault conditions (as well as the source) during an occurrence.

- SmartControl™ is pre-programmed with AutoSenz™ detection to stop lift operation during a jam or overload of the VRC carriage

Benefits:

Digital Diagnostics

- The main screen displays machine status and fault conditions as they occur with the VRC

- Maintains a record of a fault history with time stamp and fault source

- PLC status screen monitors PLC inputs, outputs and the motor current

Fault Condition History

- The SmartControl PLC stores and displays visual records of past fault conditions, eliminating guesswork when diagnosing and troubleshooting the VRC lift.

Audible Diagnostics

- The SmartControl™ call/send station immediately informs the operator that a fault has occurred (as well as the fault cause) using an audible alarm specific to the fault condition.

- Signage is available to describe the ten potential fault conditions associated with the system's audible alarm.

Overload & Jam Detection

- The SmartControl PLC includes the AutoSenz™ anti-jam sensor which protects the lift and cargo should a jam or overload occur.

SmartControl™ (Hydraulic VRCs)

The SmartControl™ system for hydraulic VRCs provides operators with immediate alerts that a fault has occurred, the specific cause of the fault and an audible alarm announcing the fault.

- Easy to read banners provided at each station and at the main control panel

- VRC Fault history is saved in the Allen Bradley SmartControl™ PLC

- The SmartControl™ controller utilizes a digital pressure transducer; No mechanical components to wear, shift or get damaged.

- The SmartControl™ will fault if the hydraulic oil pump motor is started too often, runs too long or does not build up the required pressure caused by low oil or no oil issue.

- SmartControl™ is pre-programmed with AutoSenz™ detection to stop lift operation during a jam or overload of the VRC carriage

AutoSenz "D" Series for Mechanical VRCs

The AutoSenz® D-Series VRC overload detection system is a PLC based digital user interface, with push button controls and complete system diagnostics.

Benefits:

- Continuous VRC Monitoring

- Senses Overloads

- Protects VRC/Lift Components

- Signals Owner/Operator to Action

- Provides Service and Maintenance Reminders

|

- Records VRC Fault Events & History

- Provides Extensive System Diagnostics

- Increases VRC Uptime

- Extends Lift/VRC Life

|

AutoSenz "M" Series for Mechanical and Hydraulic VRCs

AutoSenz "M" Series for Mechanical and Hydraulic VRCs

The AutoSenz™ M-Series is available for both mechanical and hydraulic VRCs. The AutoSenz M-Serie provides overload/VRC jam protection during the lifting operation.

Existing mechanical and hydraulic VRCs can be upgraded with an AutoSenz M-Series Retrofit Module. The AutoSenz M-Series Retrofit Module is available pre-wired for easy installation by a qualified VRC technician on an existing mechanical or hydraulic lift.

Benefits:

- Continuous VRC Monitoring

- Senses Overload Conditions

- Protects VRC Components

|

- Increases VRC uptime

- Extends VRC life

- Retrofit Module Available

|

LiftLok™ for VRCs

LiftLok™ for VRCs

The LiftLok™ System is a pass code protected digital keypad/key switch option for your VRC that prevents unauthorized lift operation.

The LiftLok™ key switch or LiftLok™ keypad system will ensure that only authorized staff can operate the VRC at your facility. Standard installation of the control box is usually done on the main floor; additional devices can be installed on various levels.

Two supervisory level programming codes are included in installation. Authorized lift operators can be assigned a secure 4-digit user passcode to activate the call/send control station and operate the lift. Up to 500 user passcodes can be programmed into the LiftLok™ keypad system. This allows for long service life since old user passcodes can be retired/deactivated and new codes assigned as necessary.

- Proximity Credentials Tag (Key Fob) Speeds Access for Authorized Personnel

- Weather Resistant Control Cabinet for Outdoor VRC Installations

Thomas Conveyor provides state-of-the-art engineering, automation, and controls integration solutions for manufacturing, industrial, and commercial applications. For more information on any of the VRC Control Systems shown above, please contact a Thomas Conveyor & Equipment Automation Engineer at 844 220 0086 or click on the Contact Us button above.