By Jeff Bollman

Automation Engineer

Thomas Conveyor & Equipment Co.

A manufacturer of custom bolts and domestic steel manufacturing contacted Thomas Conveyor in need of a conveyor to transport large fasteners from their forges to areas for processing. They needed to increase throughput, despite challenges due to forging temperatures and minimal handling restrictions.

The application objectives were:

- Length

A robot would place large fasteners (as long as 22”) onto the conveyor line - Temperature

The fasteners would have a temperature range up to 1100° F - Transport

The parts would cool quickly and needed to be transported on the conveyor into a large steel container located on the shop floor.

After an initial consultation, and determining if any other objectives needed addressing, we were able to determine that a Model 800 wire mesh conveyor would fit their needs well. We optimized the Model 800 to include a wire mesh over herringbone belt with a stainless steel frame.

The conveyor measured 10’ long x 12” wide, with controls and a VFD (variable frequency drive) to allow the customer adjustable speeds (3-60 FPM) depending on which part was being manufactured on the line at that time, and what the cooling cycle would be.

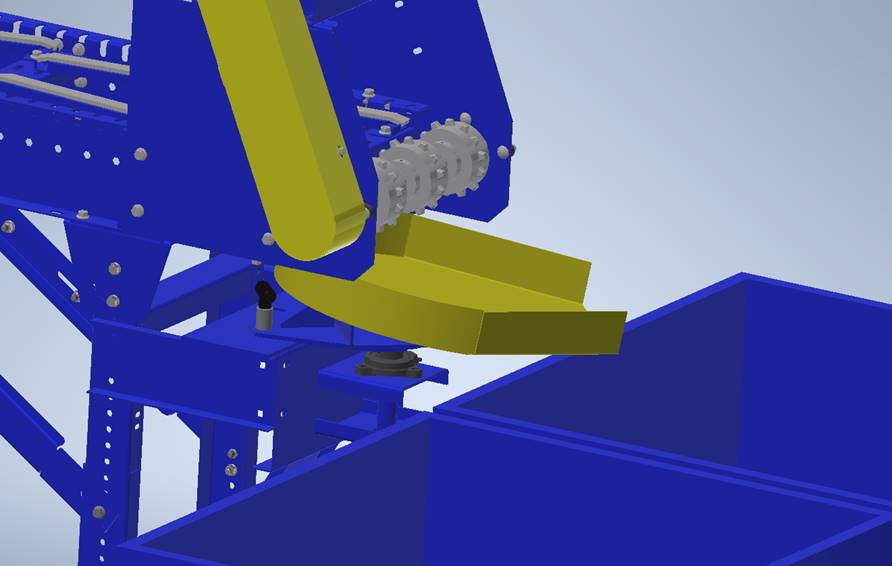

Thomas Conveyor also designed a custom chute at the discharge end that would pivot (left to right) so that the customer could fill a steel container with cooled fasteners; it also utilized a pivot-release pin to swivel the chute to an additional container so the conveyor and the production line would not have to slowed or paused to swap out containers.

The conveyor was designed with locking castors and plugs into a standard 115V outlet. The casters enable the conveyor to be relocated easily when tooling changes are needed.

The client was so pleased with the concept and design that they ordered three units to help with their upcoming busy production schedule.

Wire mesh conveyors can be used in a variety of conditions to handle hot, cold, or oily parts. They are also put into production when items need to be washed or dried.

The automation specialists at Thomas Conveyor & Equipment are here to provide you with solutions to all of your material handling needs and challenges. Contact us at 844 220 0086 for a free consultation.

The automation specialists at Thomas Conveyor & Equipment are here to provide you with solutions to all of your material handling needs and challenges. Contact us at 844 220 0086 for a free consultation.