By Mike Budz

Sales Engineer

Thomas Conveyor & Equipment Co

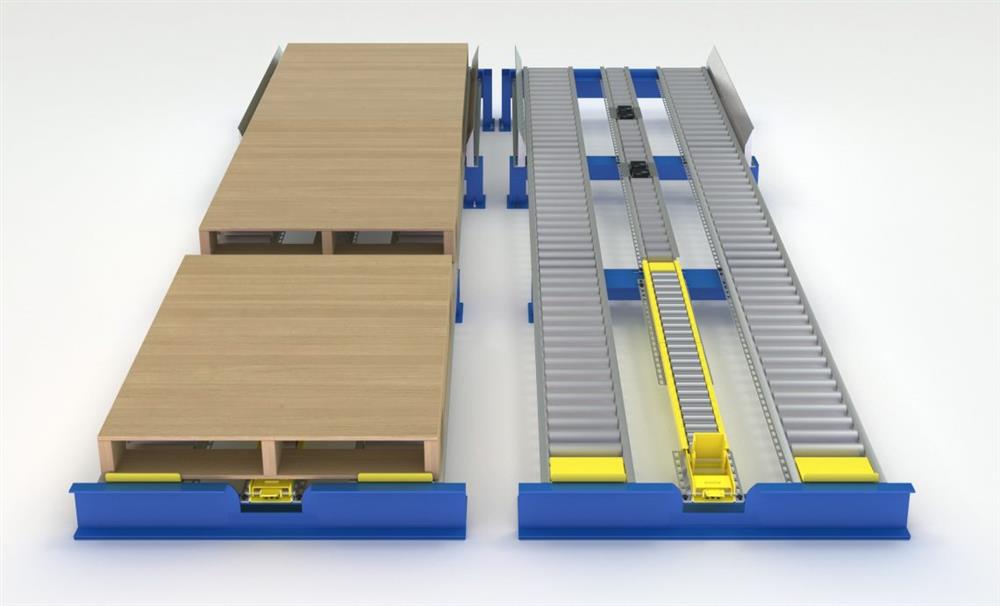

Thomas Conveyor was recently brought in by a client with an e-commerce distribution center to help them improve their picking efficiency on fast-moving SKU items. They had an existing pick module full of product pallets on their upper levels that could not be replenished fast enough. Thomas Conveyor visualized a solution by providing floor mounted, single level, magnum wheel pallet flow lanes.

The benefits of pallet flow racking is it:

The benefits of pallet flow racking is it:

- saves floor space

- boosts throughput

- reduces use of fork trucks, and

- enables first in/first out inventory control management.

After an automation solution diagnostic was completed, Thomas Conveyor engineers decided to provide twenty three single lanes of pallet flow conveyor. The pallet flow conveyor was anchored on the floor, side by side, in a straight run. Operators were able to push their picking carts down the run and pick product directly from the pallet.

The lanes allow two pallets, up to nine pallets deep, of the same SKU to be back to back pitched off the floor. Each pallet flow lane is designed to have a pallet mechanical separator provide a gap between the pitched pallets. The mechanical separator removes back pressure from secondary pallets against the first pallet.

When the front pallet is empty:

When the front pallet is empty:

- The operator lifts the empty pallet out of the line

- The operator foot activates a manual lever that allows the separator to release the second pallet to move into the first pallet position.

- Once the secondary pallet rolls past the separator, it automatically resets and detains any new pallets placed on the flow line.

- We also placed entry guides at the infeed of each lane to help the fork truck operator align the pallets into the racking lanes. These are both added safety features.

Prior to the magnum pallet flow installation, when a pallet was empty:

- The operator had to stop operations to find a pallet jack;

- Manually move up a second pallet to the front of the line; then

- Flag and position a fork truck to bring in a new full pallet, which was dangerous in this high pedestrian traffic area.

Each lane also had speed controllers, in the form of centrifugal roller brakes, that slowed the speed of the pallets moving down the line. Once the initial pallet flow conveyors were installed, the next stage of improvement was to install overhead selective pallet racking above the new conveyor system.

Each lane also had speed controllers, in the form of centrifugal roller brakes, that slowed the speed of the pallets moving down the line. Once the initial pallet flow conveyors were installed, the next stage of improvement was to install overhead selective pallet racking above the new conveyor system.

The new selective pallet racking allows the client to instantly replenish the pallet flow lane when a new pallet is required. We carefully measured the spacing between the pallet flow rails and installed uprights and beams that fit between the lanes. Each bay of racking has a wire deck to support the pallet, as well as a bolted on pallet back stop that provides the fork lift operator with a guide. The back stop also provides an extra level of security to ensure that pallets do not over reach and get pushed onto the pallet flow system.

Thomas Conveyor & Equipment provides turnkey consultation and installation for pallet flow systems. During the consultation visit sales engineers will walk the floor with the customer to chalk up and measure out production lines to ensure proper fit.

We suggest the end user ship a pallet with product for testing at the factory before we begin the manufacturing process. We provide a video showing how your pallet works on the flow racking and the satisfactory end results.

We will also provide the client with an engineered AutoCAD drawing showing plan views and elevation views of the system designed upon accepted orders.

This ensures your pallet rack system will be pitched properly and flows well. This test is done free of charge for your benefit. Once the pallet racking lanes are manufactured, our installers either union or non union, will deliver and offload the materials to the designated installation site. Installation is very quick and most projects are completed in a few days.

Contact a Thomas Conveyor Sales Engineer for a complete consultation for any of your material handling automation needs. Give us a call at 844-220-0086, and we can help to redesign or improve your existing or new pallet flow and racking systems!